Total : 2

CNC Boring Heads System

CNC Boring Heads System – Precision and Performance for Milling Applications

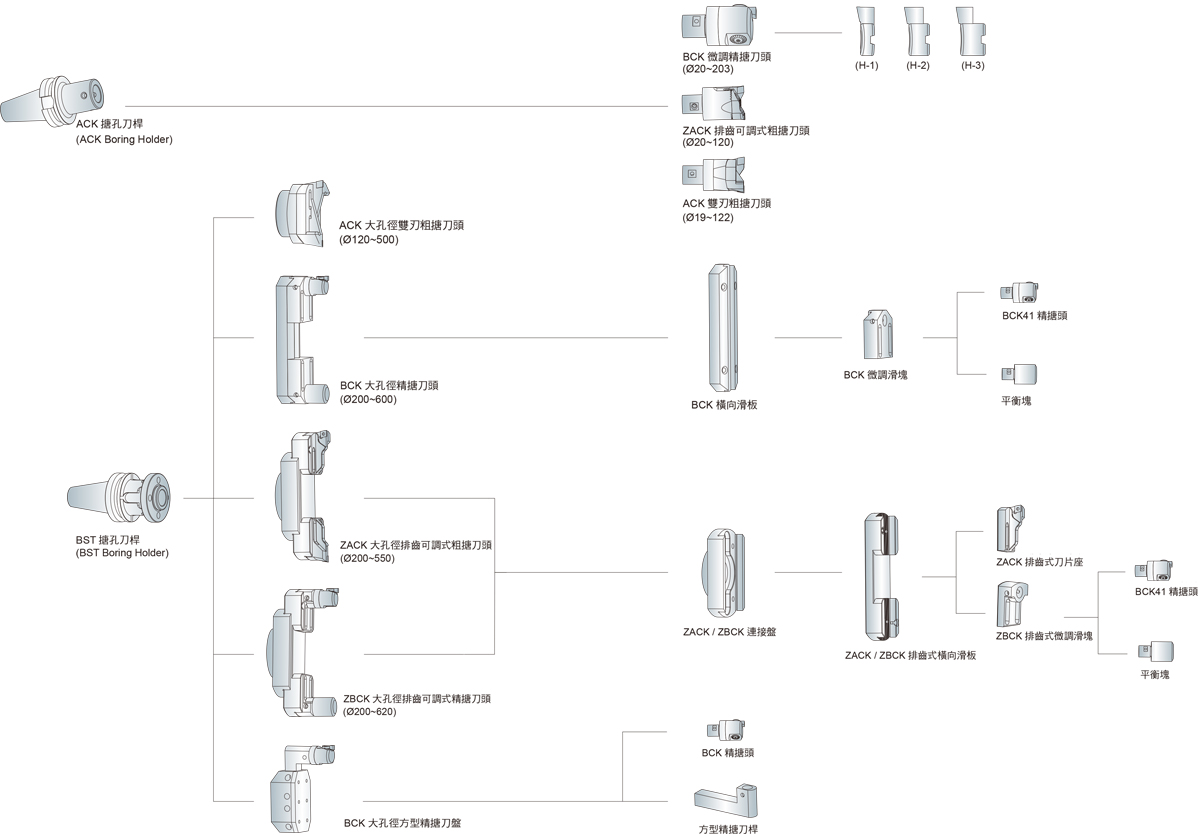

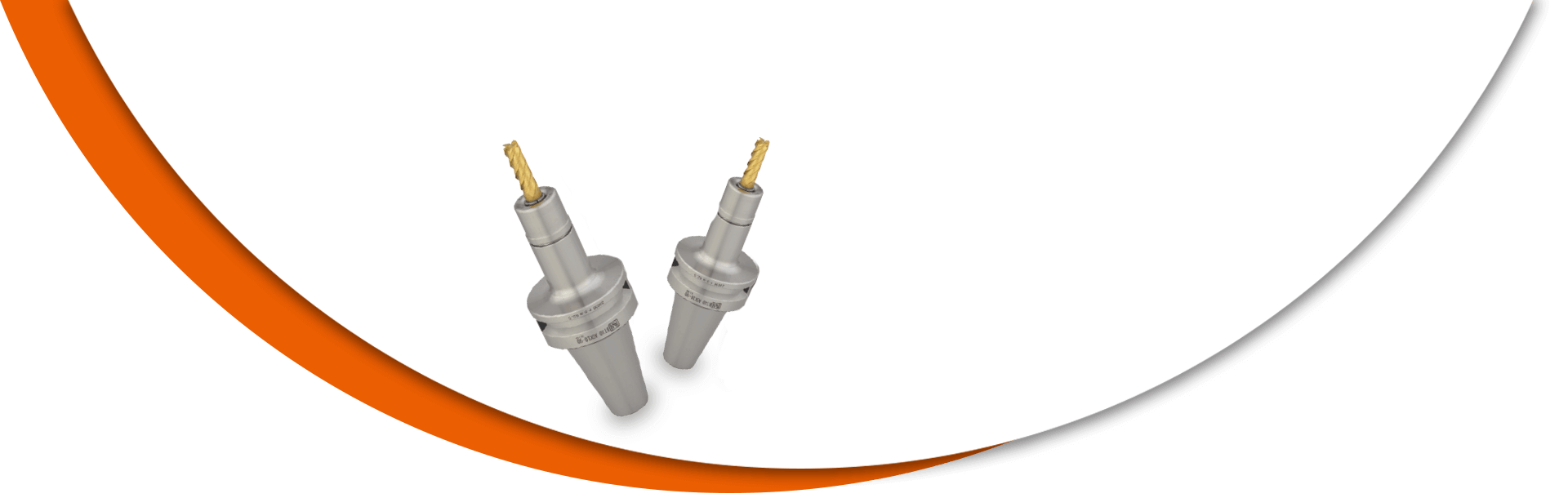

To achieve high surface integrity and dimensional accuracy in modern machining, Ann Way offers a complete range of CNC boring head solutions designed for ultimate performance, rigidity, and versatility. Whether you're performing high-efficiency rough boring or ultra-precise fine boring, our boring heads for milling machines deliver the accuracy and durability required for consistently excellent results.

Our CNC boring head system features both rough boring heads, ideal for rapid material removal and pre-finishing, and fine boring heads, which provide exceptional finishing precision, tight tolerances, and superior surface quality.

Each boring head for CNC milling is manufactured with high-quality materials and advanced engineering to minimize vibration, extend tool life, and maintain stable performance, even at large and deep hole processing. From roughing to finishing, Ann Way provides the right tools to help you optimize productivity and achieve your desired machining outcomes.

Feel free to contact us to learn more about our boring head tools or get recommendations tailored to your application.

Why Choose Ann Way CNC Boring Heads?

Our CNC boring head tools are engineered with high-strength materials and precision manufacturing to minimize vibration, extend tool life, and ensure stable performance at high spindle speeds. Every CNC boring head is built to provide consistent accuracy in a variety of machining conditions.

Available Precision Boring Head Types

Rough Boring Heads – For large-scale material removal and pre-finishing. Designed for efficient maching of boring applications.

Fine Boring Heads - Optimized for high-precision finishing, ensuring tight tolerances and excellent surface finishes.

Key Advantages of Boring Head for Milling Machine

- Stable and precise boring head for CNC milling machine

- Compatible with a wide range of milling machine setups

- Full system support for both rough and fine boring operations

- Designed to meet the needs of industries such as aerospace, automotive, mold & die, and general precision machining

Whether you're machining deep internal bores in aerospace parts or performing precision finishing in mold making, Ann Way's boring head tools ensure optimal stability and repeatability under demanding conditions.

To further enhance your machining capabilities, explore our full range of compatible Boring Holders to work seamlessly with our boring head systems for maximum efficiency and tool control.